Siemens is a multi-national company well-known for its innovative technology in critical areas of industry, infrastructure, mobility, and healthcare. Recently, it has been using this technology to create some of the most efficient and reliable supply chains and intralogistics solutions in the world. Siemens Digital Industries makes use of cutting-edge, end-to-end digital hardware and software to manage the flow of information and material goods within the walls of a warehouse, fulfillment, or distribution center and to optimize supply chains and make sure products are delivered on time, every time. This has helped the company stay competitive in an ever-changing marketplace.

Technology’s role in the world of business has become increasingly important from its use in streamlining operations and optimizing resources, businesses can now achieve a higher level of efficiency and accuracy in today’s fast-paced global economy. Siemens warehouse management system is one of the most advanced in the business, ensuring an effective way to track and manage inventory efficiently more than ever before and making use of RFID and locating solutions, as well as vision systems to get real-time product tracking. Some of the world’s largest businesses use Siemens products, including Walmart, Coca-Cola and Nestle.

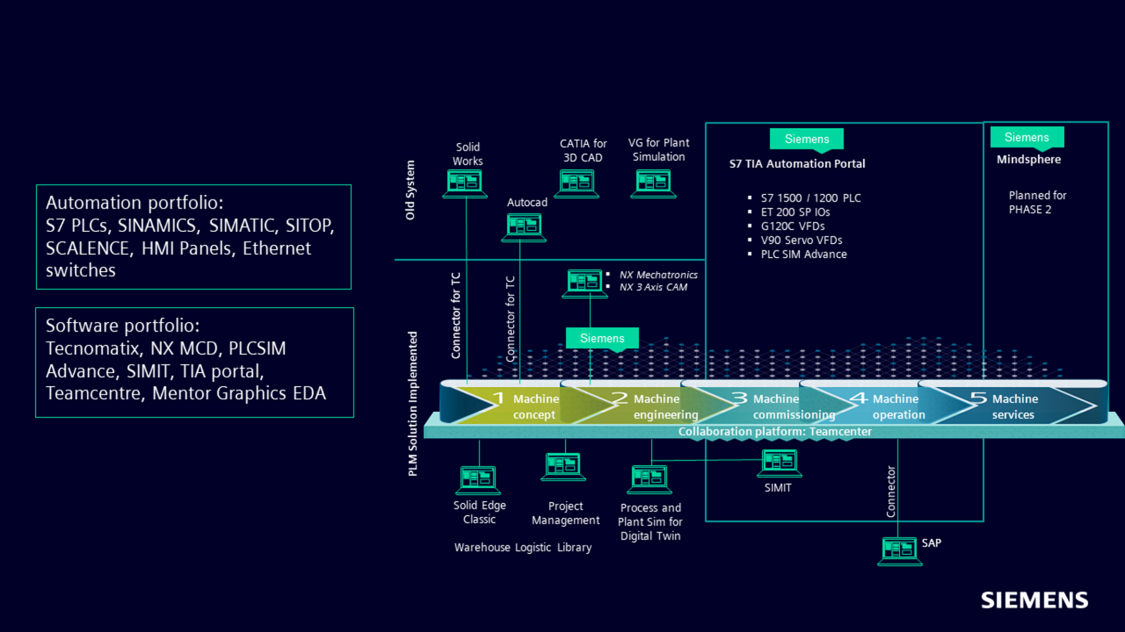

Siemens supply chain and intralogistics digital enterprise portfolio of products includes a combination of automation and software products from old and legacy systems like PLCs, HMIs and ethernet switches to newer PLM software, cloud-based and IIoT systems ensuring digital connectivity, data intelligence and logistical flow of data and products within the supply chain. Another way they are using technology to revolutionize the industry is in the use of data analytics to ensure supply chain transparency. Big data is collected and analyzed in real-time to give meaningful insights, track and identify pinpoints and potential issues within supply and distribution.

The use of virtual reality and digital twin technologies has become an increasingly popular and important tool in the industry. Businesses can have users and distributed teams immerse themselves in a realistic 3D representation of their supply chain environment, allowing them to plan, visualize and optimize their processes as well as eliminate bottlenecks. They are also using VR to design and simulate what is known as “Factories of the future”, where the different factory or warehouse layouts and processes are simulated beforehand, without incurring the huge cost of real-world construction. In addition, VR can be used to train employees giving them a realistic view of the work environment and new procedures of what they will be handling on the job.

Just like virtual reality, the digital twin technology creates a digital replica of a business’s supply chain platform or system. It goes a step further than VR however, in that the real-time status of assets and supply chain operations can be monitored and tracked, and used to improve overall efficiency, giving businesses that use this technology a competitive edge. Siemens is one of the pioneers of digital twin technology, and the company has been using this technology for years to manage their supply chain operations.

Siemens is not the only company that is using technology to create efficient supply chains. Many other companies are also using similar methods to streamline their operations and make sure that their products are of the highest quality. The way technology has revolutionized business operations, only those who embrace it will be the ones who succeed in the long run. For businesses looking to create a more efficient and reliable supply chain, investing in innovative technology is no longer an option but a necessity.